|

Resolving the concerns of sewage treatment and water-purifying plants

YOKOTA Enhanced Self-Priming Pump UPM, UPS types (PAT.)

The important life line that supports our modern lives is our water supply

and sewer systems.

Normally, we pay little attention to our use of the water supply and sewer

system until there is a disruption caused by some natural disaster, then

we realize its importance and the arduous efforts required to maintain

the system.

Recently, the role of the water supply and sewer system is becoming more

important than ever before for conservation of the natural environment.

Promoting efficiency and reducing cost are also important tasks.

YOKOTA, as a company finding solutions to water and liquid handling needs,

offers you various means of solving your concerns with pump and valve equipment

for water supply and sewer systems to help you promote efficiency and reduce

costs.

The following are some examples.

|

"Concern 1" - Sewage treatment plants |

|

|

|

When an excess amount of rainwater enters the holding tank of a sewage

treatment plant, it is discharged using a rainwater pump, although some

rainwater that could not be discharged remains in the tank.

Rainwater retained in the tank starts to decay and smell over time.

If this polluted and odorous rainwater were to be released into the river,

the river would also become polluted and smelly, resulting in environmental

problems.

Is there any appropriate method to handle this problem?

|

|

Holding tank description

|

|

|

"Concern 2" - Sewage treatment plants |

|

|

|

Sewage collecting at sewage treatment plants contains large amounts of

soil as well as pebbles and sand.

Sewage flowing into a receiving well is sent to a discharge well by a large

"screw pump" after soil in the sewage is removed by a soil extractor.

It is extremely expensive to transfer sewage from a receiving well to a

discharge well (construction, equipment, and maintenance costs).

Is there any way to effectively reduce these costs?

|

|

Screw pump external view

|

|

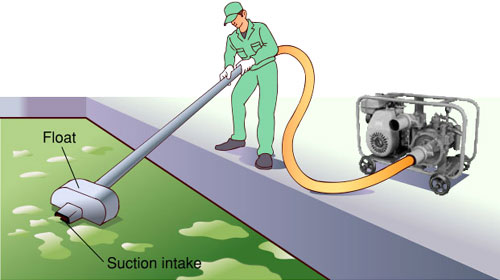

"Concern 3" - Water purification plants |

|

|

|

There are between 10 and 20 sedimentation ponds located at water purification

plants.

There is a lot of floating matter such as algae and floating grass on the

surface of sedimentation ponds.

Floating matter on sedimentation ponds is removed by hand. Removing all

of it using a net is labor intensive and expensive.

Is there an easier method?

The YOKOTA Enhanced Self-Priming Pump UPM, UPS types have addressed these

problems.

|

For "Concern 1", YOKOTA can solve environmental problems

at low cost. |

|

|

|

The YOKOTA Enhanced Self-Priming Pump UPS type can draw up retention water

from a holding tank, and then pressurize it to deliver it to a sewage treatment

plant.

As a result, polluted and odorous retention water is not released into

rivers. This pump has been highly evaluated for its role in environmental

conservation of rivers, and odor reduction from holding tanks.

A City Sewerage Bureau D Pumping Station

|

|

|

Administrative building,

rainwater drainage pump |

Rainwater drainage building,

rainwater drainage pump |

Pumped retention water |

|

A City Sewerage Bureau D Pumping Station

|

|

Rainwater drainage pump: UPS-20-1520N

|

|

|

|

A City Sewerage Bureau T Treatment Plant

|

|

Water pollution control pump: UPS-20-1520N

|

|

|

|

For "Concern 2", YOKOTA can reduce drainage transference

cost by 50%. |

|

|

|

The YOKOTA Enhanced Self-Priming Pump UPS type can easily transfer the

drainage from a receiving well to a discharge well instead of a "screw

pump". Moreover, 50% of the cost for construction, equipment, and

maintenance can be reduced.

|

Construction cost:

|

Equipment space (both inside and outside) can be reduced by approximately

50%, reducing construction cost significantly.

|

|

Equipment cost:

|

Equipment cost can be reduced by more than 50% by using the UPS type pumps.

|

|

Maintenance cost:

|

A non-clogging impeller has been adopted on the UPS type pump structure,

and YOKOTA duplex stainless steel alloy YST130N has been used on the drainage

passage for high corrosion and wear resistance. In addition, maintenance

is easier compared to submersible pumps since it is horizontally mounted

on the floor.

|

|

|

|

|

Comparison with conventional type and the YOKOTA UPS type

(image comparison including the equipment space)

|

Conventional type

|

YOKOTA UPS type

|

|

|

|

For "Concern 3", YOKOTA can improve work efficiency substantially

while reducing labor intensity. |

|

|

The YOKOTA Enhanced Self-Priming Pump UPM type removes floating matter

easily, improving working efficiency substantially, and reducing cost.

The actual work process is like using a vacuum cleaner at home.

The light YOKOTA Enhanced Self-Priming Pump UPM10 type can suction floating

matter quickly and pump it to a specified place.

If you choose the higher vacuum performance pump (option) according to

the usage, work efficiency will further improve.

|

Suction intake (test product)

|

|

|

|

About the YOKOTA Enhanced Self-Priming Pump UPM, UPS types (PAT.)

This is a volute pump with an interlocked water-air separating impeller

and a vacuum pump.

The mixture of water and air gathered in the center of the volute pump

is centrifugally separated by rotation of the water-air separating impeller

and only the air is drawn out by the vacuum pump. Therefore, the volute

pump always shows stable and supreme pumping performance without being

blocked by the air.

Unique features

|

|

Capable of continuous suction and transfer of liquids containing air or

solids such as high viscosity liquid, muddy water containing gravel, and

sewage containing empty cans (i.e., gas-solid-liquid multiphase flow).

|

|

|

Enhanced self-priming type which needs no priming liquid even at initial

operation after installation.

|

|

|

The intake piping can be constructed in many ways such as with waved pipes

or across embankments.

|

|

|

A wide variety of materials are available, including YOKOTA's corrosion

and wear resistant special stainless steel casting (YST) among others.

|

|

UPM type: Vacuum pump built-in type

|

UPS type: Vacuum pump mounted/separate types

|

|

|

For details of each product, please refer to

Enhanced Self-Priming Pump UPM, UPS types

Special Stainless Steel YST series

|