|

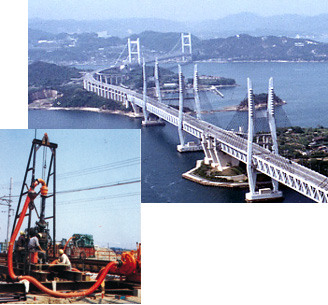

Active in large-scale, general construction projects such as the Seto Ohashi

Bridge

YOKOTA Suction Pump UPS type (PAT.)

|

| YOKOTA Suction Pump and the reverse circulation construction method |

|

The Seto Ohashi Bridge, connecting Honshu and Shikoku along the route between

Kojima and Sakaide was completed in April of 1988, taking 9.5 years, at

a total construction cost of 1.13 trillion yen.

This large project required a consolidated framework of technology across

various fields, and in the bridge abutment construction, the "reverse

circulation construction method" has been adopted for underground

excavation.

The YOKOTA Suction Pump has been used at the heart of this method.

The YOKOTA Suction Pump has also been used in construction work as follows:

|

|

Elevated foundation work for the Tohoku to Joetsu Shinkansen (bullet train)

line, opened in succession in 1982

|

|

|

Foundation work for large-scale underground LNG tanks in various areas

from 1980 to 1990

|

|

|

Foundation work for the "Tokyo Shiodome District Redevelopment Project",

which began actual construction in 1995

|

|

|

Foundation work for the "Shinagawa Shinkansen Station" opened

in 2003

|

The pump was used in many other large-scale public works projects, playing

an inconspicuous, yet vital role.

What is the reverse circulation construction method?

In accordance with the increase in construction of underground structures

and the demand by the public for the elimination of environmental degradation,

methods for eliminating noise and vibration during underground excavation

were developed.

In the reverse circulation construction method, wall faces are stabilized

using hydrostatic pressure (2 meters or more) and, instead of raising and

lowering buckets, boring is continuously done using drill bits, earth and

sand are then discharged using circulating water through the drill pipe.

|

Reverse circulation construction method

|

|

|

This water circulation method employs two types of suction systems, pump

suction and air-lift.

The pump suction system employs a pump to pump out bored earth and sand,

and this system provides wider, more general applicability under all conditions.

Why has the YOKOTA Suction Pump been chosen?

YOKOTA Suction Pumps, the largest type in our Enhanced Self-Priming Pump

(PAT.) series, are outfitted with all the necessary equipment in a modular

design that facilitates transfer to the construction site.

The mud, sand and earth siphoning main pump is connected directly to the

bleed pump (vacuum pump) to discharge air mixed in the pump. Both are set

up on a base plate with the operation control panel.

As for conventional pumping devices used in the past for the reverse circulation

construction method, mud, sand and earth penetrating the vacuum pump caused

damage or pump stoppage. However, mud, sand and earth do not penetrate

YOKOTA Suction Pumps because they are equipped with a "continuous

bleeding mechanism" (Intl. PAT.). As a result, assured, continuous

operation is possible without breakdown or pump stoppage.

Moreover, based on this "continuous bleeding", excellent suction

efficiency provides continuous, safe operation even at suction head of

-8 meters.

This is the main reason why YOKOTA Suction Pumps have received such high

marks.

Furthermore, thanks to "continuous bleeding", a receiver tank

is unnecessary, and the resulting compact size requires half the installation

area of conventional reverse circulation construction method pumping devices.

|

|

|

Model:

|

UPS-80-2520N |

|

Main pump:

|

8m3/min x 15m x 550min-1 x 45kW |

|

Vacuum pump:

|

7.5kW |

|

1:

|

Main pump

|

6:

|

Trap

|

|

2:

|

Main pump motor

|

7:

|

Operation control panel

|

|

3:

|

Vacuum pump

|

8:

|

Base plate/water tank

|

|

4:

|

Vacuum pump motor

|

9:

|

Air Intake valve

|

|

5:

|

Vacuum pump base plate

|

10:

|

Air intake pipe

|

|

|

11:

|

Receiver tank

|

|

|

Comparison of the installation space

|

|

YOKOTA Suction Pump

|

Conventional reverse circulation construction method pumping devices

|

|

|

|

|

YOKOTA Suction Pump (Enhanced Self-Priming Pump) with continuous bleeding

mechanism (PAT.)

|

|

|

The water-air separating impeller (3) is installed between the centrifugal

pump and the vacuum pump.

When operation is started, the main impeller (2) of the centrifugal pump

runs idle and the vacuum pump (5) operates, eliminating the air in the

suction pipe.

When the air is completely eliminated, the pumping liquid flows into the

pump casing, and is discharged by the main impeller (2).

The mixture of water and air in the center is drawn by the vacuum pump

(5), and goes to the water-air separating impeller (3) from behind the

main impeller.

The water-air separating impeller (3) separates the water from the air

instantly by centrifugal force.

The water returns to the suction inlet (1) through the return passage (4),

and only the air collected in the center of the water-air separating impeller

(3) is drawn out by the vacuum pump (5).

Accordingly, the centrifugal pump always operates under maximum vacuum

and bleed amount conditions, and is not blocked by the incoming air at

the pump suction inlet or the main impeller. This results in stable, high-level

pump performance.

Moreover, because the movement of the water-air separating impeller prevents

penetration of mud, sand and earth in the vacuum pump, pumping efficiency

is ensured and it is safe. |

|

|

|

1: Suction inlet

|

|

2: Main impeller

|

|

3: Water-air separating impeller

|

|

4: Return passage

|

|

5: Vacuum pump

|

|

|

Other unique features

|

|

This innovative pump can continuously suction and transport even high-viscosity

liquid, muddy water mixed with gravel, and other liquid containing air

bubbles and solid matter (i.e., gas-solid-liquid multiphase flow).

|

|

|

An enhanced self-priming pump that never requires a single drop of priming

water.

|

|

|

The intake piping can be constructed in many ways such as with waved pipes

or across embankments.

|

|

|

A wide variety of materials are available, including YOKOTA's corrosion

and wear resistant special stainless steel casting (YST).

|

Example applications and installations of the YOKOTA Suction Pump

|

Bridge pier construction above river

|

|

|

For details of this product, please refer to Enhanced Self-Priming Pump UPM, UPS types. |